Description: TB6600 4.0A Stepper Motor Driver

TB6600 arduino Stepper Motor Driveris an easy-to-use professionalstepper motor driver, which could control a two-phase stepping motor. It is compatible with Arduino and other microcontrollers that can output a 5V digital pulse signal. TB6600arduino stepper motor driverhas a wide range power input, 9~42VDC power supply. And it is able to output 4A peak current, which is enough for the most of stepper motors.The stepper driver supports speed and direction control. You can set its micro step and output current with 6 DIP switch. There are 7 kinds of micro steps (1, 2 / A, 2 / B, 4, 8, 16, 32) and 8 kinds of current control (0.5A, 1A, 1.5A, 2A, 2.5A, 2.8A, 3.0A, 3.5A) in all. And all signal terminals adopt high-speed optocoupler isolation, enhancing its anti-high-frequency interference ability.As a professional device, it is able to drive 57, 42-type two-phase, four-phase, hybrid stepper motor.

Specifications:

- Input Current: 0~5A

- Output Current: 0.5~4.0A

- Control Signal: 3.3~24V

- Power (MAX): 160W

- Micro Step: 1, 2/A, 2/B, 4, 8, 16, 32

- Temperature: -10~45℃

- Humidity: No Condensation

- Weight: 0.2 kg

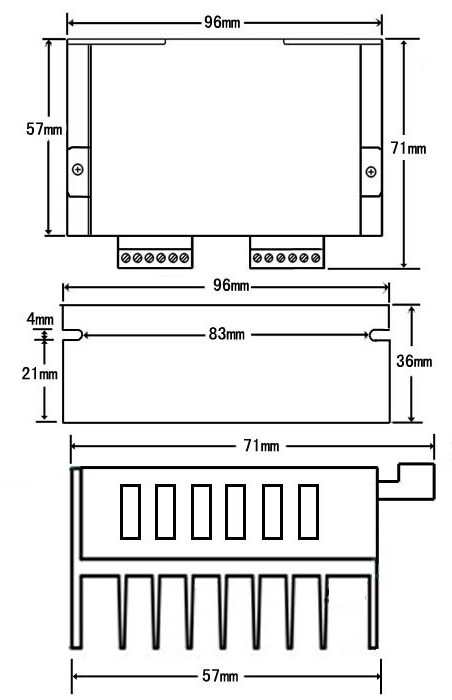

- Dimension: 96 * 71 * 37 mm

Features:

- Recommended Power : 24-36V

- Support 8 kinds of current control

- Support 7 kinds of micro steps adjustable

- The interface adopts high-speed opto coupler isolation

- Large area heat sink

- Anti-high-frequency interference ability

- Input anti-reverse protection

- Overheat, over current and short circuit protection

- Output Current:0.5~4.0A

- Power (MAX):160W

- Micro Step:

- 1, 2/A, 2/B, 4, 8, 16, 32

Electrical environment:

Subdivision setting:

- Set the pulse with 1, 2 and 3 DIP switches as follows:

Current setting:

- Use 4, 5, and 6 DIPswitches to set the running current as follows:

Diagram:

Dimensions:

Documents:

Package Included:

- 1 x TB6600 upgraded stepper motor driver

- Recommended Power : 24-36V

- Support 8 kinds of current control

- Support 7 kinds of micro steps adjustable

- The interface adopts high-speed opto coupler isolation

- Large area heat sink

- Anti-high-frequency interference ability

- Input anti-reverse protection

- Overheat, over current and short circuit protection

- Output Current:0.5~4.0A

- Power (MAX):160W

- Micro Step:

- 1, 2/A, 2/B, 4, 8, 16, 32

Login to ask a question

Global Finds

Global Finds  Quick Commerce

Quick Commerce  Grocery

Grocery  Electronics & Appliances

Electronics & Appliances  Mother, Baby & Toys

Mother, Baby & Toys _20.png) Beauty

Beauty  Sports

Sports  Automotive

Automotive  Stationery, Books & Music

Stationery, Books & Music _20.png) Fashion Luxe

Fashion Luxe  Daily Bazar

Daily Bazar _20.jpeg) Home

Home  Garden & Pet Care

Garden & Pet Care  Special Weekly Offer

Special Weekly Offer  Global Finds

Global Finds  Quick Commerce

Quick Commerce  Grocery

Grocery  Electronics & Appliances

Electronics & Appliances  Mother, Baby & Toys

Mother, Baby & Toys _20.png) Beauty

Beauty  Sports

Sports  Automotive

Automotive  Stationery, Books & Music

Stationery, Books & Music _20.png) Fashion Luxe

Fashion Luxe  Daily Bazar

Daily Bazar _20.jpeg) Home

Home  Garden & Pet Care

Garden & Pet Care  Special Weekly Offer

Special Weekly Offer